Differences between uncrosslinked and crosslinked polyethylene foam

20.04.2023

- Crosslinked PE Foam

- Uncrosslinked, also named gas-foamed, gas-filled or uncrosslinked polyethylene.

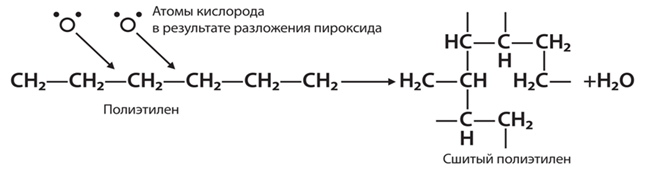

The essence of “stitching” is in that under the impact of the stitching agent in polyethylene molecular chains containing carbon and hydrogen atoms, some atoms of hydrogen become loose. The resultant free link is used for linking together hydrocarbon chains. As a result, the molecules in the chain get linked not only in a successive order, but also form lateral connections due to which the material’s physical, and to a lesser extent chemical, properties noticeably change.

Unfortunately, in our country one still encounters underhand sellers and installers offering the sale and installation of parquet boards and laminates from uncrosslinked gas-injected polyethylene foam.

Outwardly, this material is easy to distinguish from the XPE foam based on the following signs: the surface of uncrosslinked PE is wavy, irregular in thickness, semitransparent, its cells are large and uneven; during the material compression its cells collapse in which case one can hear clicks and perceive a smell of the gas.

The XPE foam is used for packaging and thermal insulation, i.e. in areas free from high stress.

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

zakaz@yurim.ru

zakaz@yurim.ru

8-800-550-26-08

8-800-550-26-08

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

zakaz@yurim.ru

zakaz@yurim.ru

8-800-550-26-08

8-800-550-26-08