Recommendations for installing sound insulation

03.11.2023

Isorulon tie underlayer is an ideal material for sound insulation of the “floating floor” inter-floor tie structures:

- It insulates structural (impact) sounds, creating a true acoustic comfort

- It retains a stable performance under high static and dynamic short duration stress

- High convenience of installation

- Environmentally friendly material

In designing and erecting the buildings, one of the serious problems the experts are confronted with is installation of an air and impact sounds insulation system.

Whereas the required air sound insulation is ensured by virtue of massive structural elements (material density and thickness) and achieved mainly at the stage of capital construction, the impact sound insulation is obtained by extra constructions of sound insulating floors.

Dynamic characteristics of XPE Foam Isorulon and an impact sound insulation improvement factor*

| Material name, thickness

|

Dynamic module of elasticity, MPa

|

Relative compression factor

|

Impact sound insulation improvement factor

?Ln, Db

|

|

Isorulon, 4mm

|

0,19

|

0,031

|

22

|

|

Isorulon, 5mm

|

0,2

|

0,029

|

24

|

|

Isorulon, 8mm

|

0,33

|

0,016

|

25

|

|

Isorulon, 10mm

|

0,34

|

0,015

|

27

|

* Impact sound insulation improvement factor ?Ln, Db obtained by a standard reinforced concrete slab 140mm thick with a “floating” tie 40 mm thick (? 100 kg/m3) laid on to a layer of XPE Foam Isorulon.

“Floating floor” is a relatively simple and effective construction of a sound insulating floor on a resilient base, used for insulating the impact sound in buildings with reinforced concrete slabs.

We recommend using, as standard, Isorulon 5 to 10 mm thick. This will effectively reduce the impact sound and provide extra hydro and heat insulation.

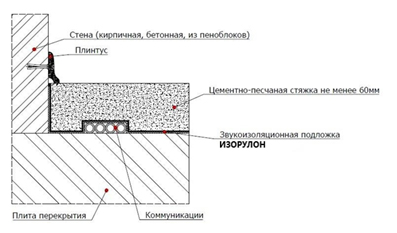

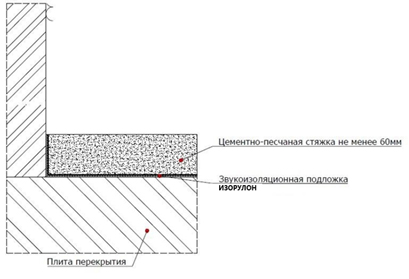

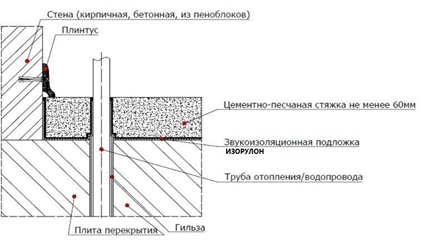

In this construction the leveling tie, at least 40 mm thick and surface density not less than 66 kg/m3, is laid on to a covering slab through a fairly thin resilient spacer of stiched foam polyethylene, Isorulon, which is brought on to the walls and other vertical elements of the indoor premises and also “enwraps” engineering communications (heat and water supply pipes) passing through the slab. We recommend bringing about 10-15 cm of Isorulon on to the wall, overlapping about 5-7 cm on the floor, and fixing by means of a metalized adhesive tape. This is necessary for blocking the sound transmission channels and creating maximum comfort for people’s life and work.

Typical Isorulon underlayer connection units:

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

zakaz@yurim.ru

zakaz@yurim.ru

8-800-550-26-08

8-800-550-26-08

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

2 Pervomaiskaya st., Dubna urban settlement, Dubensky district, Tula region

zakaz@yurim.ru

zakaz@yurim.ru

8-800-550-26-08

8-800-550-26-08